Tidy3D mode solver#

Tidy3D includes an open-source FDFD mode solver for simulating waveguide modes.

Waveguides#

Guided electromagnetic modes are those with an effective index larger than that of the waveguide cladding.

In the example below, we have a silicon waveguide (n = 3.4) surrounded by a SiO₂ cladding (n = 1.44). For a waveguide with dimensions of 220 nm in height and 450 nm in width, the effective index is calculated to be 2.466.

import gdsfactory as gf

import gplugins.tidy3d as gt

import matplotlib.pyplot as plt

import numpy as np

from gdsfactory.generic_tech import get_generic_pdk

gf.config.rich_output()

PDK = get_generic_pdk()

PDK.activate()

nm = 1e-3

strip = gt.modes.Waveguide(

wavelength=1.55,

core_width=0.5,

core_thickness=0.22,

slab_thickness=0.0,

core_material="si",

clad_material="sio2",

)

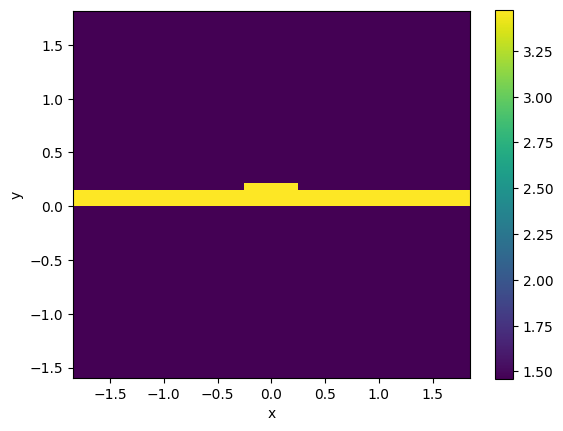

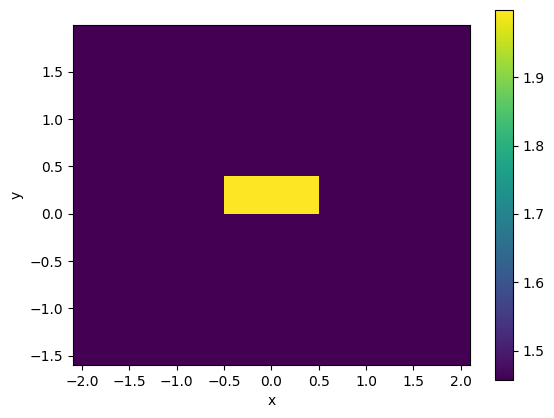

strip.plot_index()

<matplotlib.collections.QuadMesh object at 0x7ff66d176f90>

strip.plot_grid()

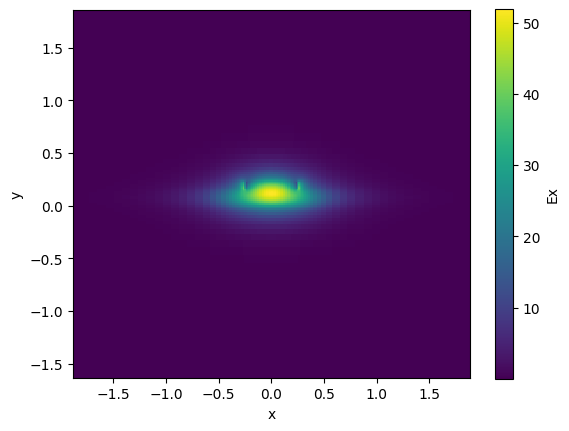

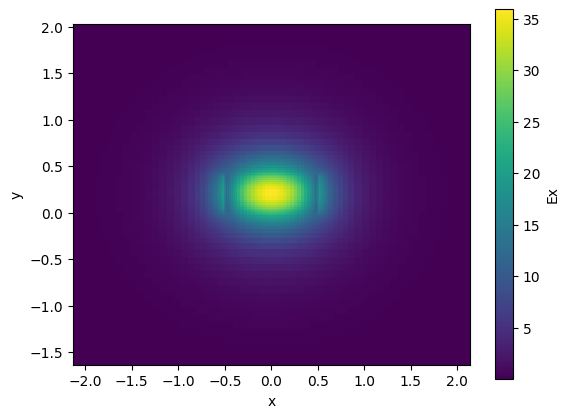

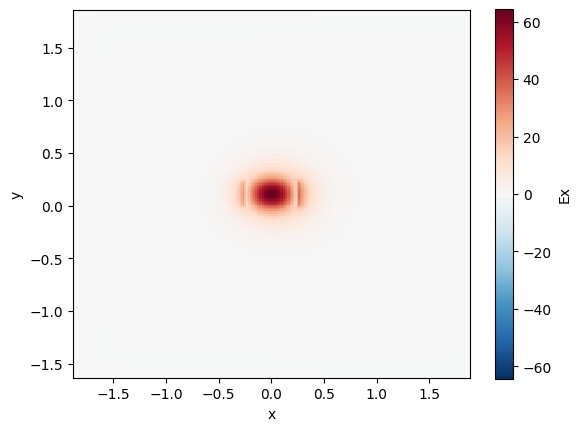

strip.plot_field(field_name="Ex", mode_index=0) # TE

<matplotlib.collections.QuadMesh object at 0x7ff66ad90c10>

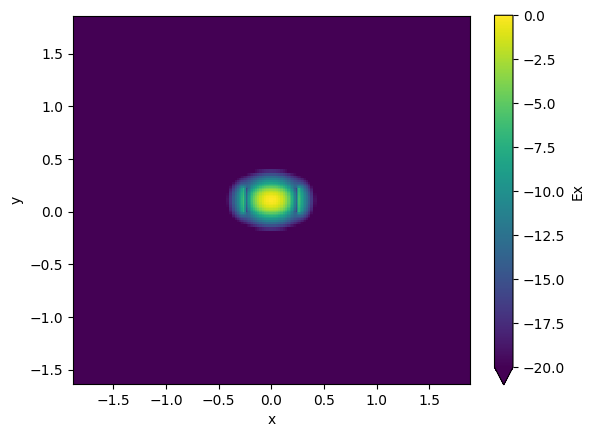

strip.plot_field(field_name="Ex", mode_index=0, value="dB") # TE

<matplotlib.collections.QuadMesh object at 0x7ff66adf7590>

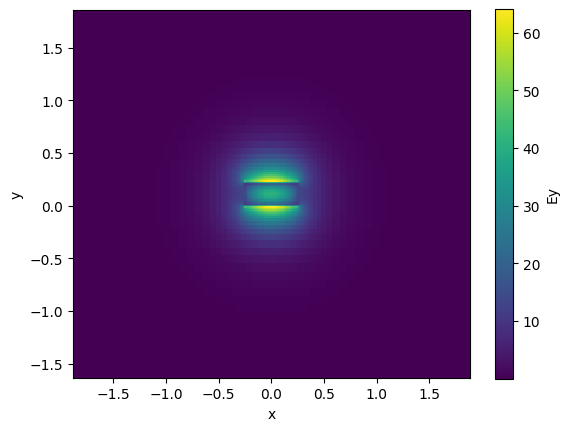

strip.plot_field(field_name="Ey", mode_index=1) # TM

<matplotlib.collections.QuadMesh object at 0x7ff66ab06b10>

strip.n_eff

array([2.51134734+4.42777628e-05j, 1.86463643+2.09422901e-04j])

rib = gt.modes.Waveguide(

wavelength=1.55,

core_width=0.5,

core_thickness=0.22,

slab_thickness=0.15,

core_material="si",

clad_material="sio2",

)

rib.plot_index()

rib.n_eff

array([2.67427418+3.10179974e-05j, 2.50854926+4.47861069e-05j])

rib.plot_field(field_name="Ex", mode_index=0) # TE

<matplotlib.collections.QuadMesh object at 0x7ff66aaaec10>

nitride = gt.modes.Waveguide(

wavelength=1.55,

core_width=1.0,

core_thickness=400 * nm,

slab_thickness=0.0,

core_material="sin",

clad_material="sio2",

)

nitride.plot_index()

nitride.n_eff

array([1.64461788+8.05914279e-05j, 1.57796343+1.42713228e-04j])

nitride.plot_field(field_name="Ex", mode_index=0) # TE

<matplotlib.collections.QuadMesh object at 0x7ff66a80d6d0>

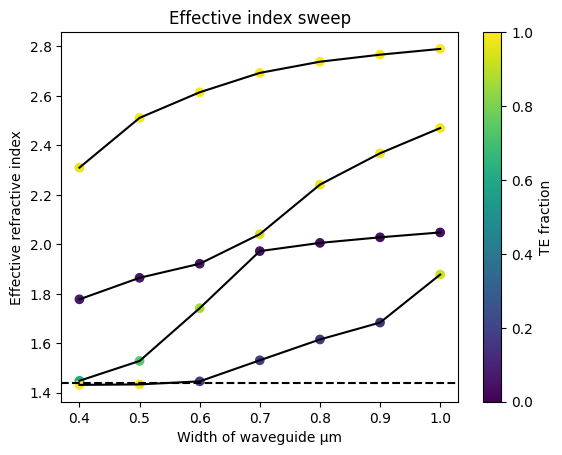

Sweep width#

You can sweep the waveguide width and compute the modes.

By increasing the waveguide width, the waveguide supports many more TE and TM modes. Where TE modes have a dominant Ex field and TM modes have larger Ey fields.

Notice that waveguides wider than 0.450 um support more than one TE mode. Therefore the maximum width for single mode operation is 0.450 um.

strip = gt.modes.Waveguide(

wavelength=1.55,

core_width=1.0,

slab_thickness=0.0,

core_material="si",

clad_material="sio2",

core_thickness=220 * nm,

num_modes=4,

)

w = np.linspace(400 * nm, 1000 * nm, 7)

n_eff = gt.modes.sweep_n_eff(strip, core_width=w)

fraction_te = gt.modes.sweep_fraction_te(strip, core_width=w)

for i in range(4):

plt.plot(w, n_eff.sel(mode_index=i).real, c="k")

plt.scatter(

w, n_eff.sel(mode_index=i).real, c=fraction_te.sel(mode_index=i), vmin=0, vmax=1

)

plt.axhline(y=1.44, color="k", ls="--")

plt.colorbar().set_label("TE fraction")

plt.xlabel("Width of waveguide µm")

plt.ylabel("Effective refractive index")

plt.title("Effective index sweep")

Text(0.5, 1.0, 'Effective index sweep')

Exercises

What is the maximum width to support a single TE mode at 1310 nm?

For a Silicon Nitride (n=2) 400nm thick waveguide surrounded by SiO2 (n=1.44), what is the maximum width to support a single TE mode at 1550 nm?

For two 500x220nm Silicon waveguides surrounded by SiO2, what is the coupling length (100% coupling) for 200 nm gap?

Group index#

You can also compute the group index for a waveguide.

nm = 1e-3

strip = gt.modes.Waveguide(

wavelength=1.55,

core_width=500 * nm,

slab_thickness=0.0,

core_material="si",

clad_material="sio2",

core_thickness=220 * nm,

num_modes=4,

group_index_step=10 * nm,

)

print(strip.n_group)

[4.17803969 4.08299706 2.71577378 1.50332985]

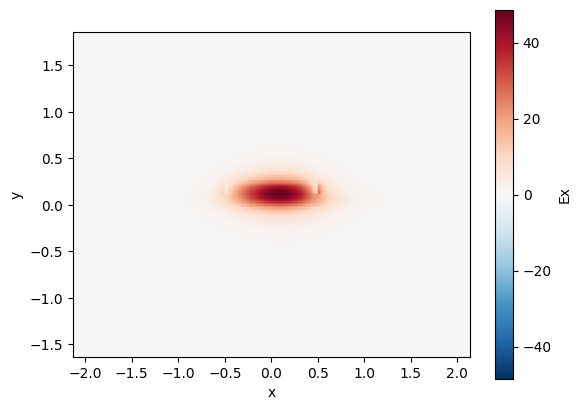

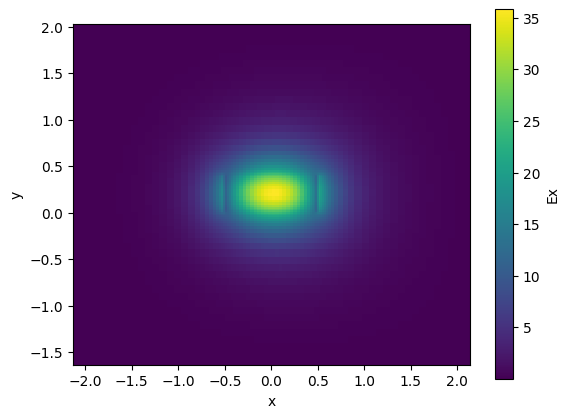

Bend modes#

You can compute bend modes specifying the bend radius.

strip_bend = gt.modes.Waveguide(

wavelength=1.55,

core_width=500 * nm,

core_thickness=220 * nm,

slab_thickness=0.0,

bend_radius=4,

core_material="si",

clad_material="sio2",

)

strip_bend.plot_field(field_name="Ex", mode_index=0) # TE

<matplotlib.collections.QuadMesh object at 0x7ff66974e550>

Bend loss#

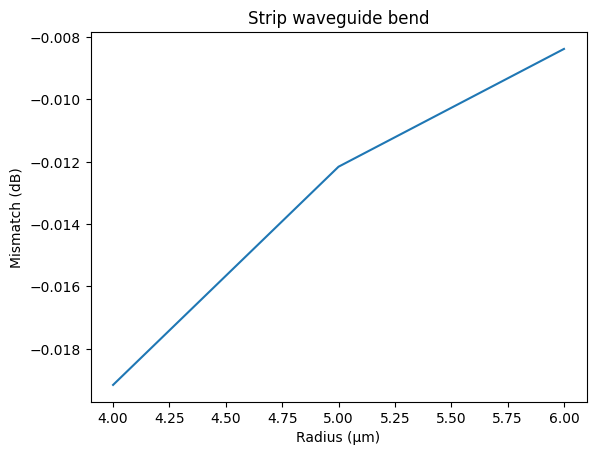

You can also compute the losses coming from the mode mismatch from the bend into a straight waveguide. To compute the bend loss due to mode mismatch you can calculate the mode overlap of the straight mode and the bent mode. Because there are two mode mismatch interfaces the total loss due to mode mismatch will be squared (from bend to straight and from straight to bend).

radii = np.arange(4, 7)

bend = gt.modes.Waveguide(

wavelength=1.55,

core_width=500 * nm,

core_thickness=220 * nm,

core_material="si",

clad_material="sio2",

num_modes=1,

bend_radius=radii.min(),

)

mismatch = gt.modes.sweep_bend_mismatch(bend, radii)

plt.plot(radii, 10 * np.log10(mismatch))

plt.title("Strip waveguide bend")

plt.xlabel("Radius (μm)")

plt.ylabel("Mismatch (dB)")

Text(0, 0.5, 'Mismatch (dB)')

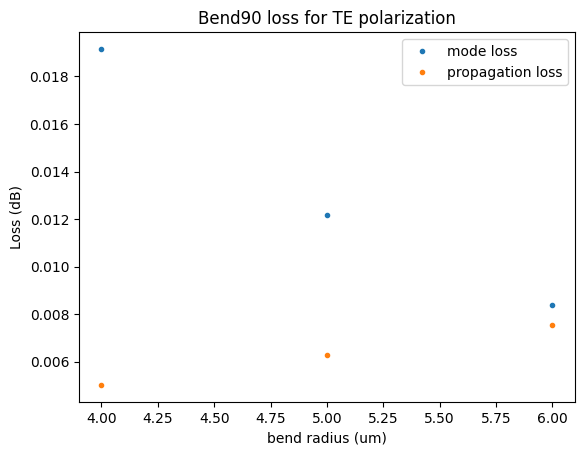

dB_cm = 2 # dB/cm

length = 2 * np.pi * radii * 1e-6

propagation_loss = dB_cm * length * 1e2

print(propagation_loss)

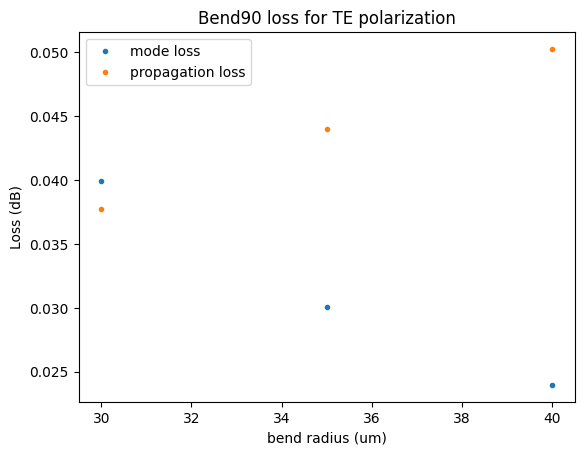

plt.title("Bend90 loss for TE polarization")

plt.plot(radii, -10 * np.log10(mismatch), ".", label="mode loss")

plt.plot(radii, propagation_loss, ".", label="propagation loss")

plt.xlabel("bend radius (um)")

plt.ylabel("Loss (dB)")

plt.legend()

[0.00502655 0.00628319 0.00753982]

<matplotlib.legend.Legend object at 0x7ff669433590>

rib = gt.modes.Waveguide(

wavelength=1.55,

core_width=1000 * nm,

core_thickness=220 * nm,

slab_thickness=110 * nm,

bend_radius=15,

core_material="si",

clad_material="sio2",

)

rib.plot_field(field_name="Ex", mode_index=0) # TE

<matplotlib.collections.QuadMesh object at 0x7ff669426690>

nitride_bend = gt.modes.Waveguide(

wavelength=1.55,

core_width=1000 * nm,

core_thickness=400 * nm,

slab_thickness=0.0,

bend_radius=30,

core_material="sin",

clad_material="sio2",

)

nitride_bend.plot_field(field_name="Ex", mode_index=0, value="abs") # TE

<matplotlib.collections.QuadMesh object at 0x7ff6694d6790>

radii = np.array([30, 35, 40])

bend = gt.modes.Waveguide(

wavelength=1.55,

core_width=1000 * nm,

core_thickness=400 * nm,

core_material="sin",

clad_material="sio2",

num_modes=1,

bend_radius=radii.min(),

)

mismatch = gt.modes.sweep_bend_mismatch(bend, radii)

dB_cm = 2 # dB/cm

length = 2 * np.pi * radii * 1e-6

propagation_loss = dB_cm * length * 1e2

print(propagation_loss)

plt.title("Bend90 loss for TE polarization")

plt.plot(radii, -10 * np.log10(mismatch), ".", label="mode loss")

plt.plot(radii, propagation_loss, ".", label="propagation loss")

plt.xlabel("bend radius (um)")

plt.ylabel("Loss (dB)")

plt.legend()

[0.03769911 0.0439823 0.05026548]

<matplotlib.legend.Legend object at 0x7ff66931b590>

Exercises

For a 500nm wide 220nm thick Silicon waveguide surrounded by SiO2, what is the minimum bend radius to have less than 0.04dB loss for TE polarization at 1550nm?

For a 500nm wide 220nm thick Silicon waveguide surrounded by SiO2, what is the minimum bend radius to have 99% power transmission for TM polarization at 1550nm?

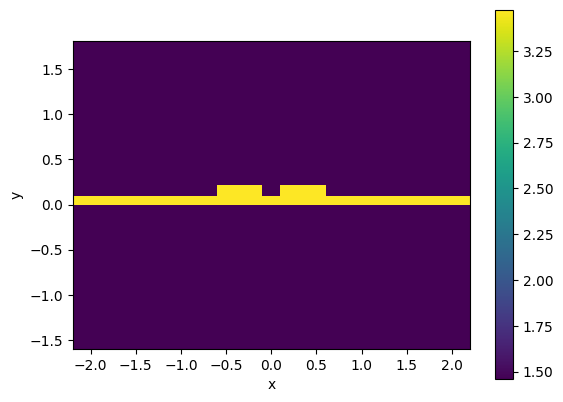

Waveguide coupler#

You can also compute the modes of a waveguide coupler.

ore_width[0] core_width[1]

<-------> <------->

_______ _______ _

| | | | |

| | | |

| |_____| | | core_thickness

|slab_thickness |

|_____________________| |_

<----->

gap

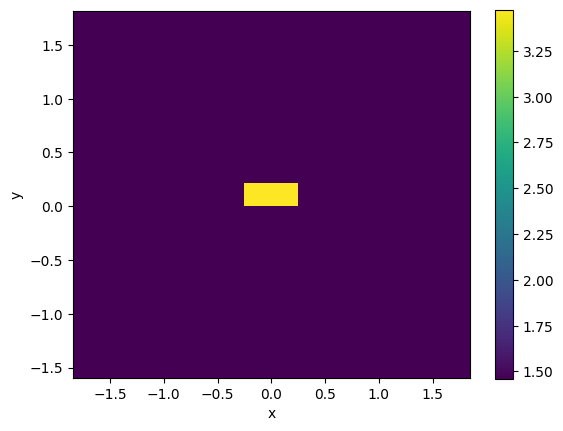

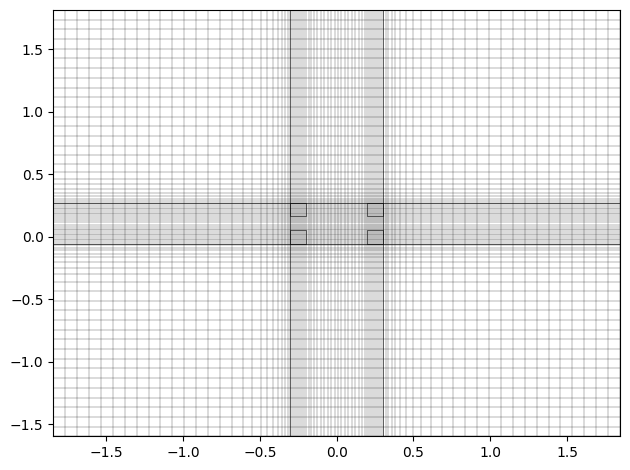

c = gt.modes.WaveguideCoupler(

wavelength=1.55,

core_width=(500 * nm, 500 * nm),

gap=200 * nm,

core_thickness=220 * nm,

slab_thickness=100 * nm,

core_material="si",

clad_material="sio2",

)

c.plot_index()

<matplotlib.collections.QuadMesh object at 0x7ff6693d6690>

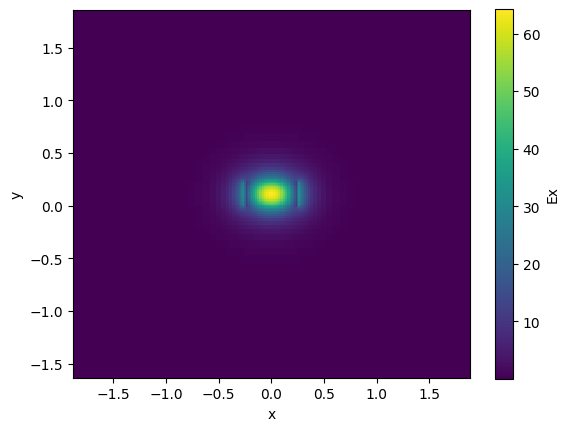

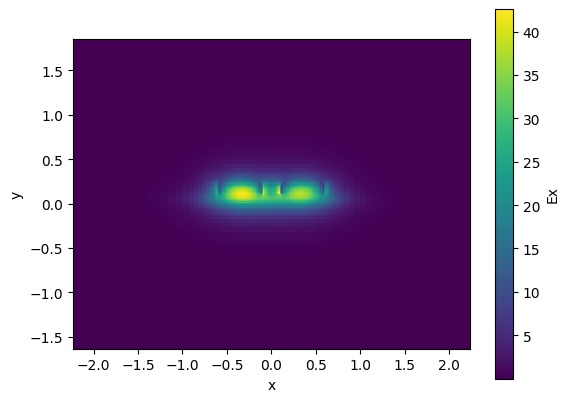

c.plot_field(field_name="Ex", mode_index=0) # TE

<matplotlib.collections.QuadMesh object at 0x7ff66aa4da90>

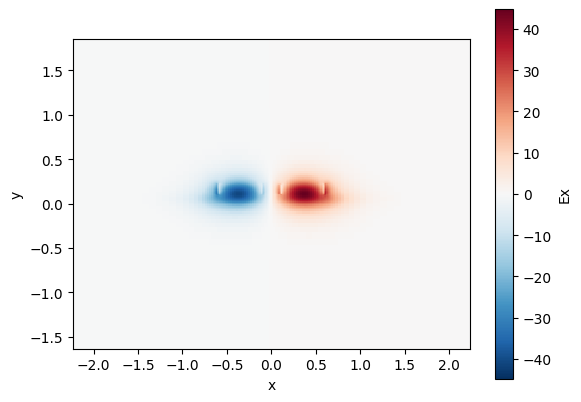

c.plot_field(field_name="Ex", mode_index=1) # TE

<matplotlib.collections.QuadMesh object at 0x7ff668c09a50>

coupler = gt.modes.WaveguideCoupler(

wavelength=1.55,

core_width=(450 * nm, 450 * nm),

core_thickness=220 * nm,

core_material="si",

clad_material="sio2",

num_modes=4,

gap=0.1,

)

print("\nCoupler:", coupler)

print("Effective indices:", coupler.n_eff)

print("Mode areas:", coupler.mode_area)

print("Coupling length:", coupler.coupling_length())

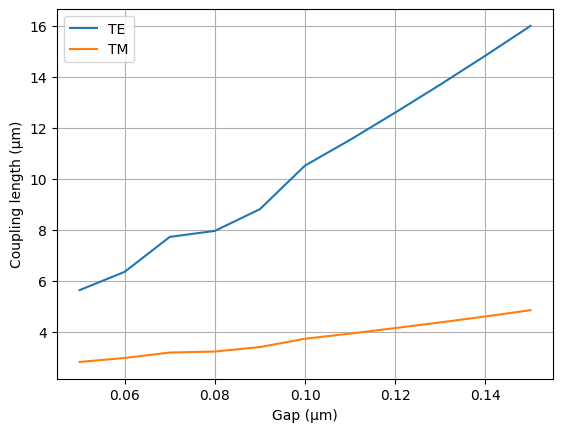

gaps = np.linspace(0.05, 0.15, 11)

lengths = gt.modes.sweep_coupling_length(coupler, gaps)

_, ax = plt.subplots(1, 1)

ax.plot(gaps, lengths)

ax.set(xlabel="Gap (μm)", ylabel="Coupling length (μm)")

ax.legend(["TE", "TM"])

ax.grid()

Coupler: WaveguideCoupler(wavelength=array(1.55), core_width=['0.45', '0.45'], core_thickness='0.22', core_material='si', clad_material='sio2', box_material=None, slab_thickness='0.0', clad_thickness=None, box_thickness=None, side_margin=None, sidewall_angle='0.0', sidewall_thickness='0.0', sidewall_k='0.0', surface_thickness='0.0', surface_k='0.0', bend_radius=None, num_modes='4', group_index_step='False', precision='double', grid_resolution='20', max_grid_scaling='1.2', cache_path='/home/runner/.gdsfactory/modes', overwrite='False', gap='0.1')

Effective indices: [2.4637647 +6.57552457e-05j 2.39007229+5.06214923e-05j

1.9225165 +1.99036730e-04j 1.71420814+2.37015946e-04j]

Mode areas: [0.31003254 0.33258301 0.57286555 0.59002858]

Coupling length: [10.5166863 3.72044606]